Product

laminating

machine

laminating

machine

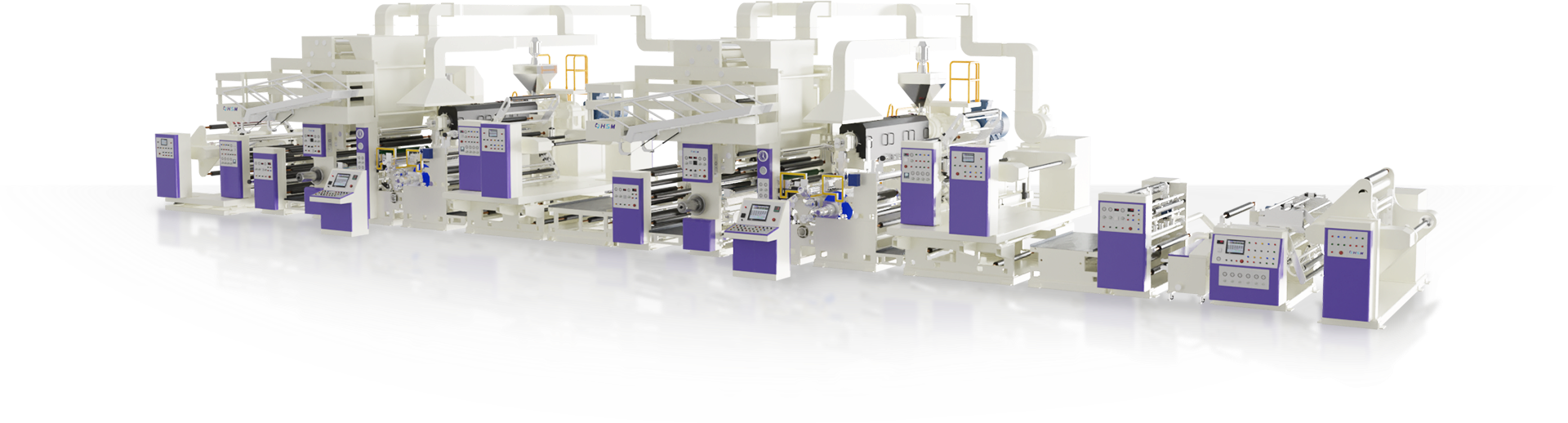

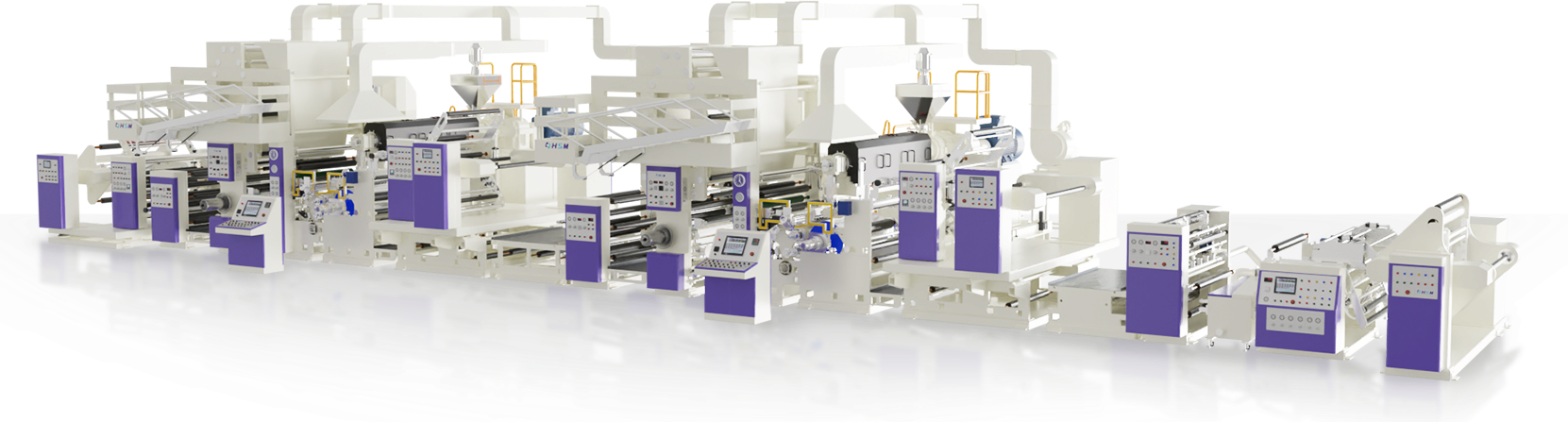

Tandem Extrusion Coating Laminating Machine

[ Tandem Extrusion Coating Laminating Machine ]

The tandem extrusion coating laminator produces high quality composite materials through coating and laminating work on various materials. This equipment is applicable to various materials such as film, paper, aluminum and nonwoven, in particular, plays a key role in packaging materials, industrial materials and special application fields. The tandem extrusion coating system maximizes production efficiency by producing multilayer composite materials in one pass through continuous coating and laminating operations. The precise control system optimizes thickness, temperature and pressure at each stage, and provides strong bonding between various materials. In addition, the automated raw material supply and energy saving design enables effective work, and the design that considers safety and maintenance guarantees the worker’s safety. This equipment is the optimized choice that can perform high quality tandem coating and laminating, which are necessary in various industrial fields, rapidly and effectively.

Product Information

SPECIFICATION

-

Type of Resin

PE, EVA, PP, Etc -

Guide Width

1,300~2,100mm -

Kind of Web

Plastic films & AL foil, Paper -

Machine Speed

Max. 250m/min -

1st Unwind Dia

Max Ø800 / Turret type -

Extruder

Single / Co-extruder -

2nd Unwind Dia

Ø600 / Turret type -

Extruder L/d

30:1 ~ 36:1 -

Rewiding Dia

Ø1000 / Turret type -

Cooling Roll Dia

Ø600 -

Web Width

1,200~2,000mm -

Main Drive Motor

AC Vector motor

* Please use the specification for reference only.

Main Features

-

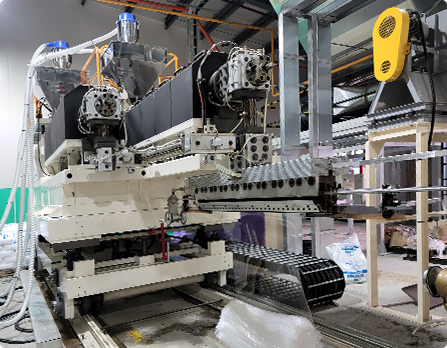

Co-Extruder Unit

-

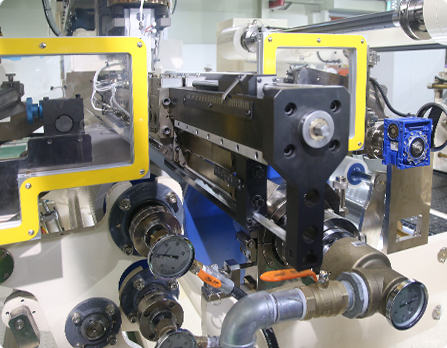

Cooling & Nip Roll Unit

-

Gravure Coating Unit